-

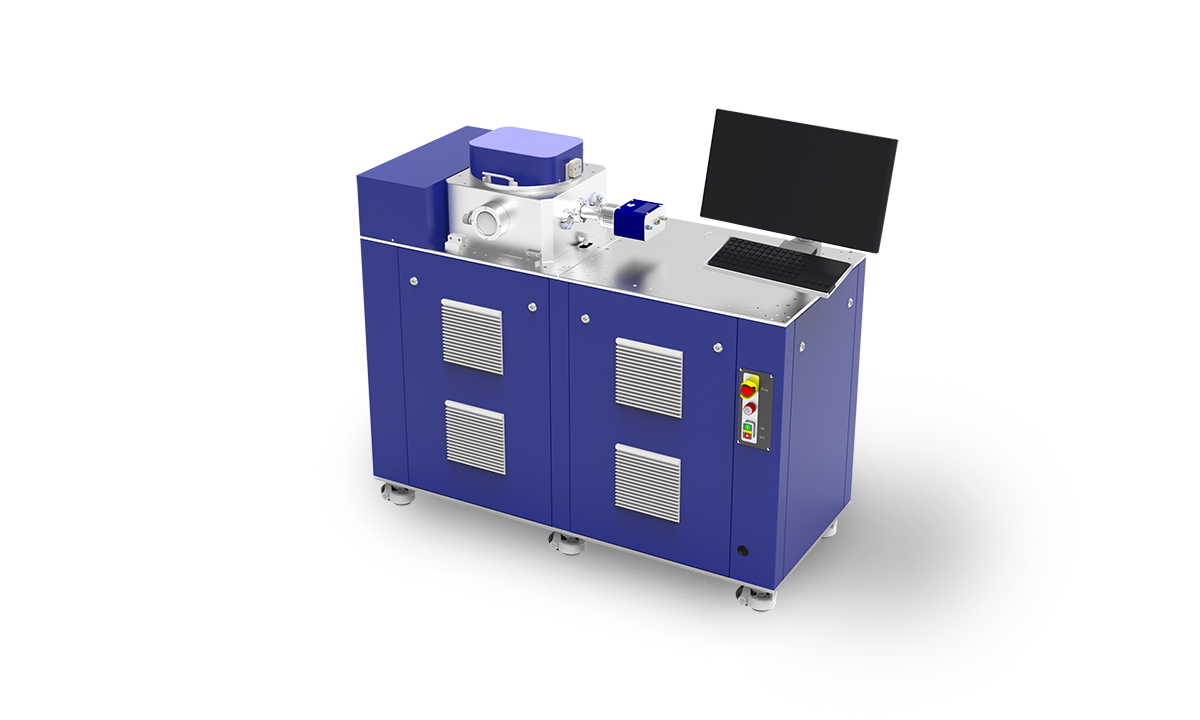

SEM Series

-

Semiconductor thin film measurementHard coating measurement

Utilizing top-tier brand oil-free dry pumps and molecular pump combinations to achieve a clean vacuum pressure of 10-3 Pa, typically with vacuuming time less than 30 minutes.

Equipped with high-quality constant power magnetron sputtering power supplies to ensure consistent deposition rates. Also, featuring an automatic rotating lifting sample stage, capable of applying bias voltage and plasma sources for substrate cleaning and activation. Particularly suitable for the preparation of 4-6 inch metal film electrodes, achieving excellent film thickness, uniformity, and adhesion.

Convenient operation with touch screen PC menu for editable process software implementation for automatic control. Plug and play. No additional cooling water, no need for 380V high voltage, no need for compressed air. The equipment is compact, silent, and occupies minimal floor space.