-

SEM Series

-

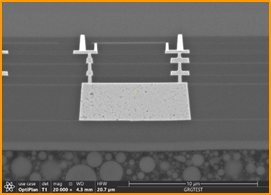

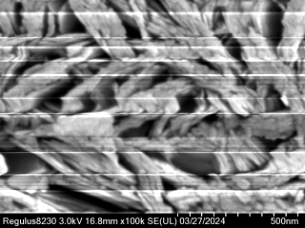

Semiconductor thin film measurementHard coating measurement

|

|

Technical Specifications |

|

Application Scenarios |

Conductive Coating Preparation for HR/UHR FE-SEM Samples |

|

Vacuum Pump |

Rotary Vane Pump |

|

Pumping Speed |

≥4m3/h |

|

Ultimate Vacuum |

<1Pa |

|

Working Pressure |

4-10Pa |

|

Pumping Down Time |

<2-3Min |

|

Sputtering Timer |

0-300S |

|

Vacuum Gauge |

Pirani Vacuum Gauge |

|

Chamber Dimension |

~Ø150×120mm |

|

Rotary Sample Stage |

Diameter: 80mm; Rotation Speed: 60RPM; TSD: 55-70mm continuously adjustable |

|

Sputtering Target |

Ø30×0.2-1mm/2pcs, Single-Target sputtering and Dual-Target Sequential sputtering |

|

Sputtering Power |

Constant Power Magnetron Sputtering DC Power Supply ( Max.30W, Max.100 mA, 0-800V DC ) |

|

Operation Mode |

Touchscreen control, the control system provides interlock protection function |

|

Weight |

Main Unit~15kg |

|

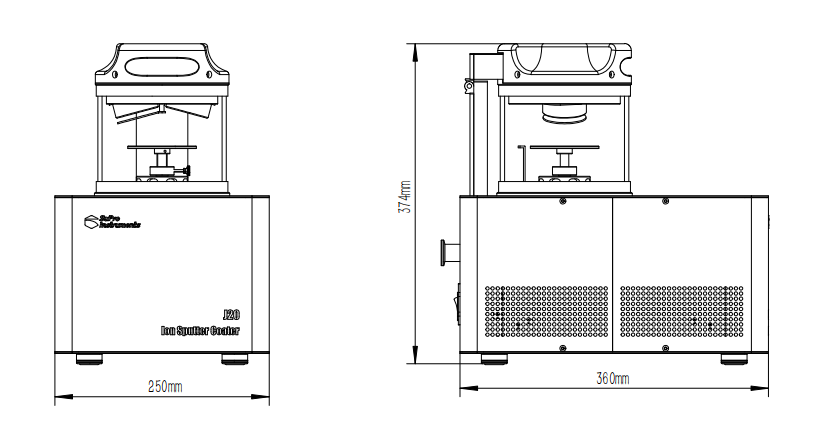

Dimension |

~250mm W×360mm D×374mm H |

|

Power Supply |

100-240V AC, 50/60Hz Grounded Three-prong Plug |

|

Power Consumption |

<500W |

|

Warranty |

1 Year |

|

Remarks |

The technical specifications and parameters listed above will be updated without prior notice. If you have any questions, please contact us. |

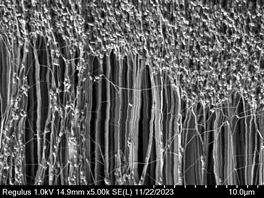

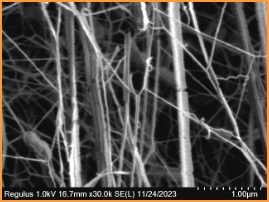

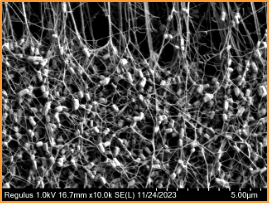

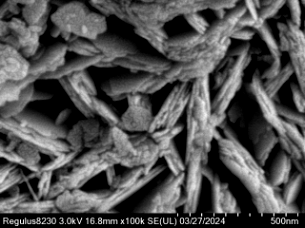

Under the same sputtering conditions, gold (Au) exhibits a significant charge elimination effect, but the Au particles are clearly visible. Platinum (Pt) does not eliminate charge, and in Pt-Au layered samples, there is neither charge nor clear visibility of metal particles.

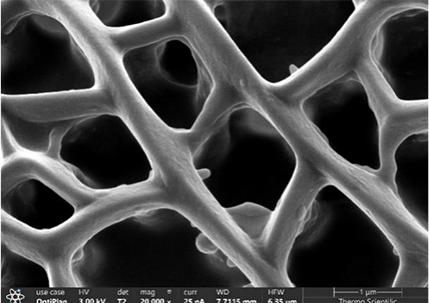

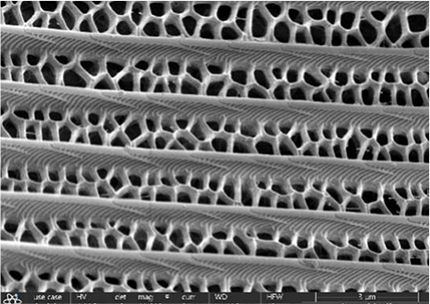

For 3D sample scenarios (powder, porous, fibers, etc., analogous to mountain roads): The J20 tilt angle dual cathode, rotation deflection and layering process achieves comprehensive multi-angle large-area deposition, with better charge and image effects than single-target Pt sputtering.